Commonly used in agriculture, food processing, mining, cement production, and many other industries that require vertical transportation of bulk materials.

![]()

![]()

Price::$1,000.00-$6,400.00/Set

Consult now and enjoy a 10% discount

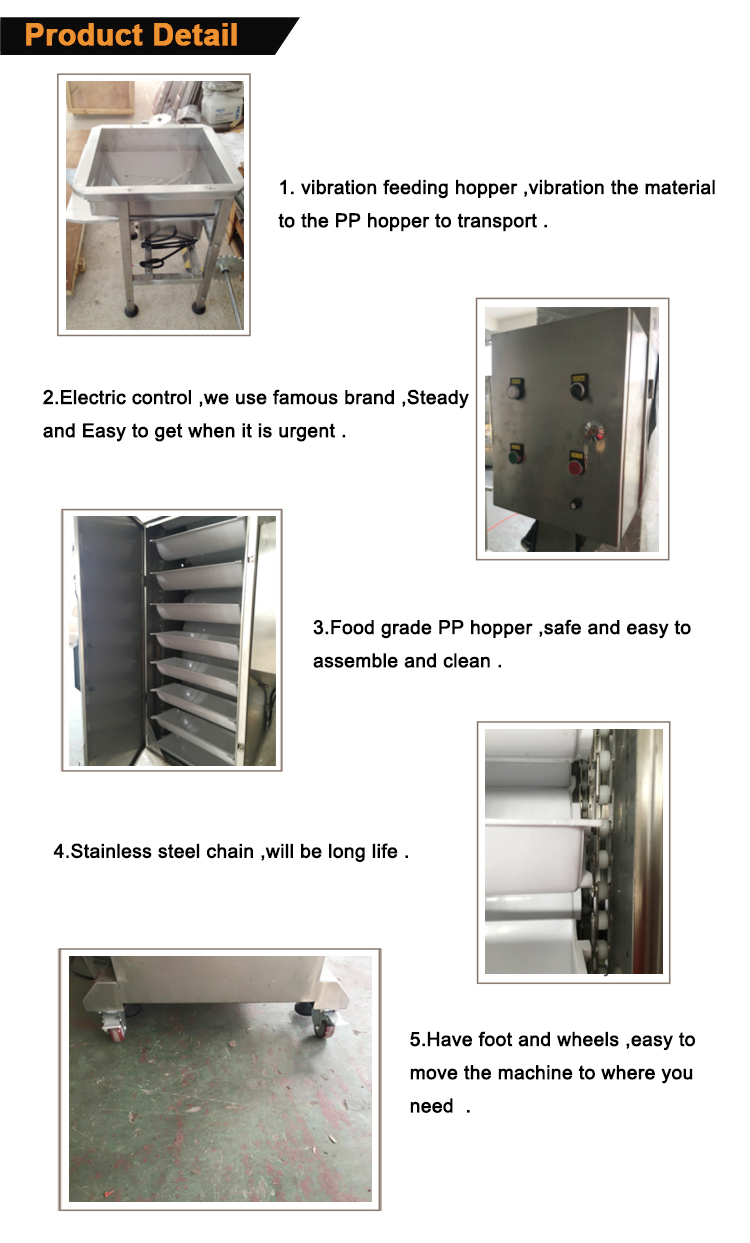

Bucket Material: Food Grade PP

Conveying Speed: 2-5 m³/h

Bucket Volume: 1.8L, 4.0L, and 6.0L (Customizable)

Discharge Height: 2-12 m

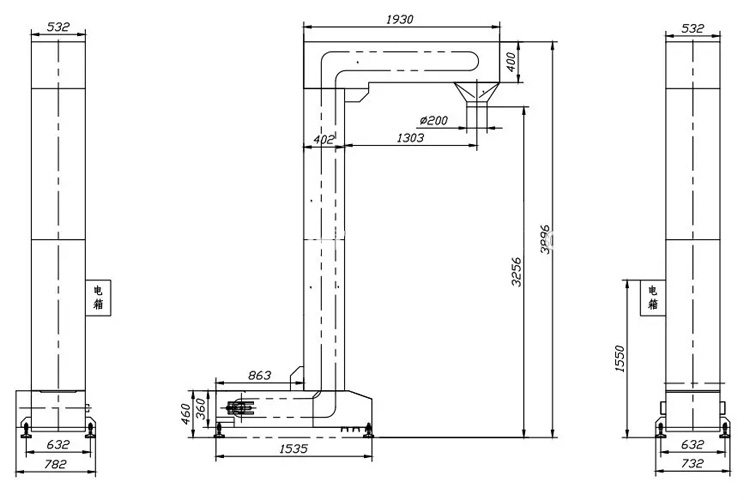

In-Feed Length: 863 mm

Out-Feed Length: 1930 mm

conveying capacity: 3-10m³/h

Number of Outlet(s):Single or Muti-dicharge outlets

Application: Can handle a variety of materials including grains, seeds, powders, aggregates and other bulk solids.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

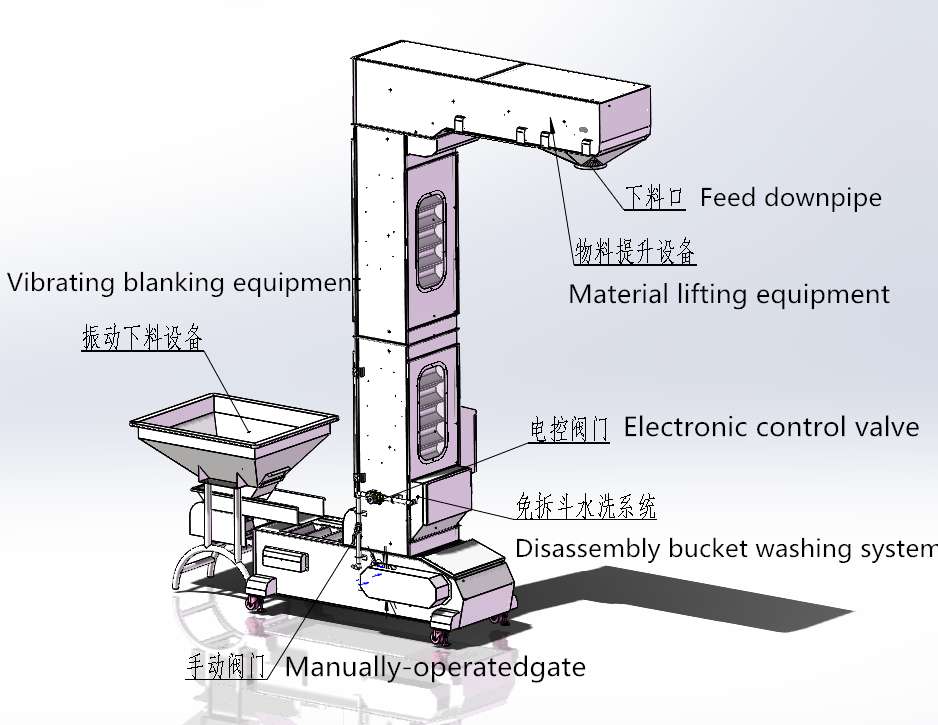

Bucket elevator with hopper is a vertical conveying system used to lift and convey bulk materials vertically, and has a feed hopper at the bottom to collect and supply materials. It combines the vertical conveying function of a traditional bucket elevator with a specially designed feed hopper to facilitate the feeding and initial conveying of materials.

The hopper is located at the bottom of the elevator and serves as a collection point for the materials to be conveyed. The buckets are attached to the belt or chain and are designed to scoop up the materials from the hopper as the belt or chain moves upwards. Once the buckets reach the top, they tip over and discharge the materials into the desired location, such as a silo, conveyor, or processing equipment.

There are many benefits to using a hopper in conjunction with a bucket elevator, here are some of the benefits of installing a hopper:

1. Control the material flow: As the initial loading point of the elevator, the hopper can control the material flow. By properly designing the size and shape of the hopper, precise delivery and control of materials can be achieved. This helps avoid excessive or insufficient material supply and improves production efficiency and process stability.

2. Balance material distribution: The hopper can help balance the distribution of materials in the elevator. It evenly distributes materials into barrels, preventing excessive concentration or accumulation in specific areas, thereby reducing the risk of imbalance and blockage between barrels.

3. Reduce environmental pollution: By using a hopper, the flying and spilling of materials during loading can be reduced or prevented. This helps reduce environmental pollution and clean-up of work areas.

Bucket elevator with hopper is a common conveying equipment, usually used to convey granular materials in vertical or inclined directions, such as grains, granules, powder, etc. This equipment combines the functions of a bucket elevator and a hopper, which can effectively improve the material conveying efficiency and capacity. The following are some common types of bucket elevator with hopper:

| Types | Continuous Bucket Elevator with Hopper | Intermittent Bucket Elevator with Hopper | Chain Bucket Elevator with Hopper | Belt Bucket Elevator with Hopper |

| Img |  |

|

|

|

| Features | It has a continuous bucket elevator structure that runs along a fixed track through one or more chains or belts to lift materials from the bottom of the hopper to the top. The hopper is located at the top of the elevator and is used to receive and release materials. | An intermittent working mode has been added to more accurately control the delivery and transportation of materials. | Chains are used as transmission devices to connect bucket elevators together to form a continuous conveying system. The hopper runs along a fixed track through a chain, lifting the material from the bottom to the top. | Belt bucket elevators use rubber or metal belts as transmission devices to connect hoppers together to realize material transportation. |

| Application | Suitable for lifting bulk materials such as grain, ore, coal, cement, etc. | Suitable for lifting lumpy or granular materials, such as coal, ore, granulated fertilizers, etc. | It is suitable for conveying powdery, granular and small pieces of low-grinding materials. Such as: coal, cement, gravel, sand, chemical fertilizers, etc. | It is suitable for conveying large amounts of materials and situations where smooth conveying is required. |

A bucket elevator with a hopper works on the principle of vertical lifting and material transportation using buckets attached to a belt or chain loop. Here is a step-by-step explanation of how it operates:

Material Loading: The process begins with the material being loaded into the hopper, which is located at the bottom of the bucket elevator. The hopper serves as a collection point for the material and provides a controlled feed into the buckets.

Bucket Filling: As the elevator starts operating, the belt or chain loop moves, and the buckets are carried from the bottom to the top. As the buckets move through the material in the hopper, they scoop up or collect the material.

Material Transport: As the buckets continue their upward movement, they carry the collected material along with them. The buckets are designed to retain the material inside while in motion, preventing spillage.

Discharge: When the buckets reach the top of the elevator, they tilt or invert, allowing the material to be discharged into the desired location. This can be a storage bin, a processing unit, or a conveyor system for further transportation.

Efficient material loading

The hopper at the bottom of the bucket elevator allows easy and controlled loading of materials. It provides large capacity for collecting and supplying materials, ensuring a smooth and continuous feeding process.

Improve material safety

The hopper acts as a containment function, preventing material from spilling or scattering during loading. It helps maintain a clean and safe work environment by containing materials within the elevator system.

Enhanced material flow control

The hopper helps in the controlled discharge of material into the elevator bucket. It ensures consistent feed rates and prevents material surges, promoting smooth and reliable conveying operations.

Versatile Material Handling

Bucket elevators with hoppers can handle a variety of bulk materials, including powders, granules, and even friable or abrasive materials. Hopper designs can be customized to suit specific material characteristics and flow requirements.

Reduce downtime and maintenance

The hopper and bucket elevator combination minimizes material spillage and buildup, reducing the need for frequent cleaning and maintenance. It helps optimize operational efficiency and reduce downtime.

System design flexibility

The integration of the hopper with the bucket elevator provides flexibility in system layout and configuration. The hopper can be positioned at a variety of angles, allowing vertical, horizontal or tilted feeding, depending on the specific requirements of the application.

| bucket volume | 1.8L | 3.6L | 6.5L |

| bucket material | pp | ss304 | ABS |

| body material | mild steel | stainless steel | --- |

| NO.S of discharge port | single | muti-discharge port | --- |

| output | 4-6m3/h | 6.5-8m3/h | 5.5-12m3/h |

| voltage(v) | 220v/240v/as you need | 380v/415v/440v/as you need | as you need |

| speed | adjustable | ||

| conveying capacity | 3-10m3/h | ||

A bucket elevator with a hopper usually consists of the following main components:

Hopper: The hopper is the bottom section of the bucket elevator that serves as the collection point for the lifted material. It controls the feed to the hopper and ensures a constant supply of material.

Bucket: Attached to a belt or link and responsible for scooping up material from a hopper and conveying it vertically. Buckets are designed with specific shapes and sizes based on the characteristics of the material being handled.

Belt or Chain: The buckets in a bucket elevator are attached to a continuous endless belt or chain that moves the buckets in a vertical direction. The choice of belt or chain depends on application requirements, material properties and operating conditions.

Head: Consists of a motor, gearbox, and other components that provide the power to drive the belt or chain and move the bucket. The head also includes a discharge chute or spout for discharging material.

Guide Section: Provides support and tension to the belt or chain. It usually includes tensioners, pulleys and tensioning systems to maintain proper tension and alignment of the belt or chain.

Enclosure: Usually enclosed within a case or casing to ensure safety, dust protection, and prevent material spillage during transport. The shell is designed to provide structural support and can be made of materials such as steel or reinforced plastic.

Bucket elevator with hopper can be custom designed according to specific needs and applications. Here are some possible customization types:

1. Size and capacity customization: The size and capacity of the barrel elevator and hopper can be customized according to the needs of material processing and production capacity requirements.

2. Material selection and customization: According to the characteristics of the materials being processed, appropriate materials can be selected to manufacture the elevator and hopper. For example, for corrosive materials, corrosion-resistant materials can be selected for customization.

3. Customized hopper design: The shape, size and outlet position of the hopper can be customized according to the characteristics and fluidity of the material to ensure good material flow and control.

4. Safety feature customization: Safety switches, protection devices to prevent overload and other safety features can be customized according to safety needs to ensure the safety of the operation process.

Bucket elevators with hoppers are used in various applications in various industries. Here are some common applications:

1. Grain processing: used to process grains such as wheat, corn, rice, barley and soybeans. They are used to transport grain from above ground storage facilities or silos to a higher level for processing, cleaning or storage.

2. Seed processing: used to process and move different types of seeds, including oilseeds, beans and vegetable seeds. The hopper acts as a collection point for the seed before it is lifted and transported to other processing equipment or storage bins.

3. Food processing: used to process bulk food, such as grains, nuts, seeds and powder. They are used for vertical conveying at all stages of food processing, including cleaning, sorting and packaging.

4. Chemical and pharmaceutical industry: used to handle bulk materials such as powder, granules and pellets. They are used to transport these materials vertically for mixing, blending, packaging or storage.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.