Guano, as an organic fertilizer, plays an important role in agricultural production. However, the particles in guano vary in size, and in order to take full advantage of its fertility, it needs to be screened and graded. In this regard, the guano sieving machine has become an indispensable piece of equipment that can improve the quality of guano and agricultural production efficiency, and help farmers make better use of guano.

Guano (such as bird or bat feces, also known as "guano" or "guano") is a natural organic fertilizer that is rich in nutrients such as nitrogen, phosphorus, and potassium and is beneficial to crop growth. When using guano as fertilizer, the main purposes of screening are the following:

1. Remove impurities and foreign matter: Bird droppings may contain impurities, foreign matter or other substances that are not conducive to crop growth, such as stones, branches, residual branches and leaves, etc. Through screening, these impurities and foreign matter can be removed, ensuring that pure fertilizer is applied to the crops.

2. Uniform particle size: Sieving can separate bird droppings into particles of different sizes, making the fertilizer particles uniform in size. This helps ensure even application of fertilizer and ensures that the nutrients in the fertilizer are fully absorbed by the crop.

3. Improve fertilizer utilization: Through screening, particles that are too large or too small can be removed to make the fertilizer particles of moderate size to improve fertilizer utilization. Proper particle size helps the fertilizer release nutrients in the soil and be efficiently absorbed and utilized by crops.

4. Improve the fertilization effect: The screened bird droppings are more likely to be evenly mixed with the soil, which is beneficial to the release of nutrients and the absorption of nutrients by crops, thereby improving the fertilization effect and promoting crop growth.

The screening process for guano is as follows:

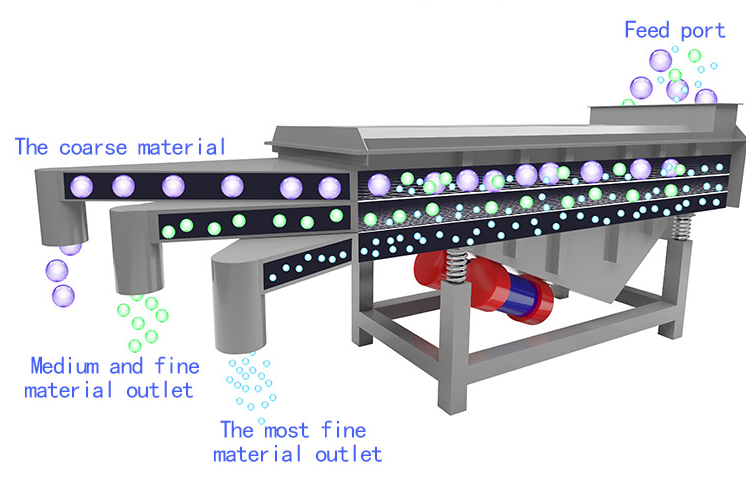

1. Feeding: Put the bird droppings into the feeding port of the sieving machine.

2. Vibrating screening: Start the vibrator to vibrate the screen box, and the bird droppings will produce oscillating motion on the screen. Depending on the screen aperture, smaller particles of bird droppings pass through the screen into the receiving opening below, while larger particles are blocked above the screen.

3. Multi-stage screening: Through the multi-layer screen setting, the bird droppings can be further screened in multiple stages to separate them into grades of different particle sizes.

4. Collection and subsequent processing: The screened guano particles are collected, packaged or processed as needed.

1.Enhanced Product Quality: By ensuring uniform particle size and removing impurities, the sieving machine helps maintain high-quality guano fertilizer.

2.Increased Efficiency: The machine automates the sieving process, leading to higher throughput and productivity in guano processing operations.

3.Cost-Effective: Guano sieving machines offer a cost-effective solution for processing and preparing guano fertilizer by optimizing the sieving process.

4.Dust Control: Some guano sieving machines are equipped with dust control features such as dust covers or collection systems to minimize airborne particles and maintain a clean working environment.

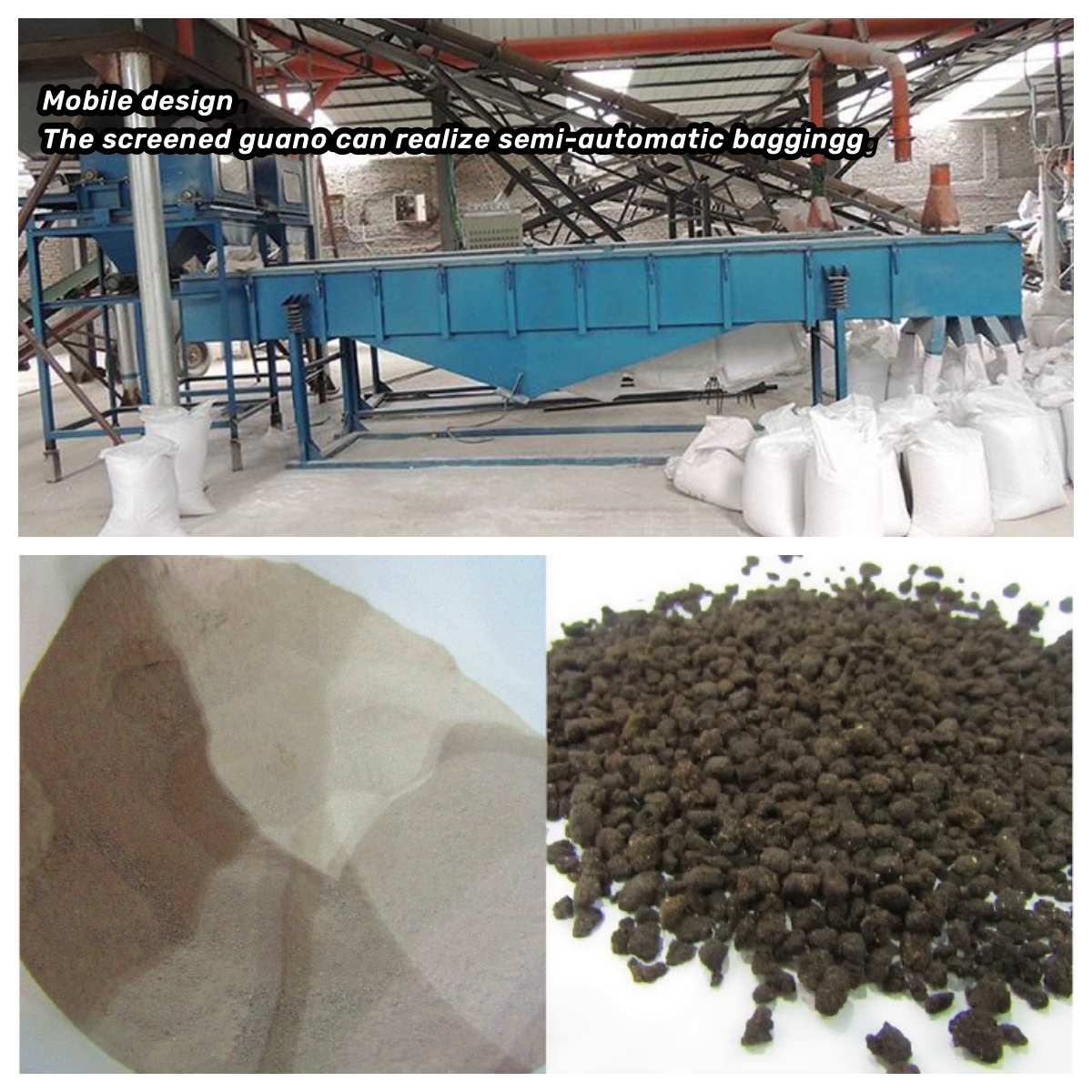

5.Mobility and Portability: Depending on the specific model, some guano sieving machines may be portable and easy to move. This feature allows for flexibility in different work areas or locations where guano processing is required.

6.Durability and Easy Maintenance: The sieving machine is built with durable materials that can withstand the corrosive nature of guano. It is easy to clean and maintain, ensuring long-term reliability and minimizing downtime.

1. Movement: Guano collection points are usually located in bird habitats or areas where birds are concentrated. These locations may be widely distributed and not fixed. Therefore, the guano sieving machine needs to be mobile and can be quickly moved and deployed between different sites to meet the needs of guano collection and reduce the time and cost of transportation and handling. This is also important for large-scale guano. Collecting and processing items is very important.

2. Dust-proof device: Bird droppings may produce dust during the screening process, affecting the working environment and the health of operators. In addition, the guano itself may give off an unpleasant odor and cause inconvenience to the operator. During use of the guano sieving machine, a dust cover can be installed to prevent product spillage or reduce dust problems.

3. Automatic bagging: Guano sievig machines can often be used in conjunction with automatic bagging systems to automatically bag the guano after screening. This automatic bagging system can greatly improve the efficiency and convenience of bird droppings processing.

3. Breakable: During the screening process of guano, larger guano clumps may be dispersed into smaller particles through the action of vibration and screen.

These cases demonstrate the application of guano screening machines to different types of customers. Whether it is a farmer cooperative or a guano processing and export company, the guano screening machine plays a key role in helping them process and utilize guano resources efficiently.

As a powerful tool to improve agricultural production efficiency, the guano sieving machine can not only improve the quality and utilization rate of guano fertilizer, but also reduce the waste of resources in agricultural production. Its widespread application will bring more convenience and benefits to agricultural production and promote the process of sustainable agricultural development. If you are interested, please feel free to contact me.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.