Urea is a widely used chemical and an essential raw material in fields such as fertilizers and cosmetics. In order to produce high-quality urea products, urea granules need to be screened and finely processed. This will use the urea particle vibrating screen.

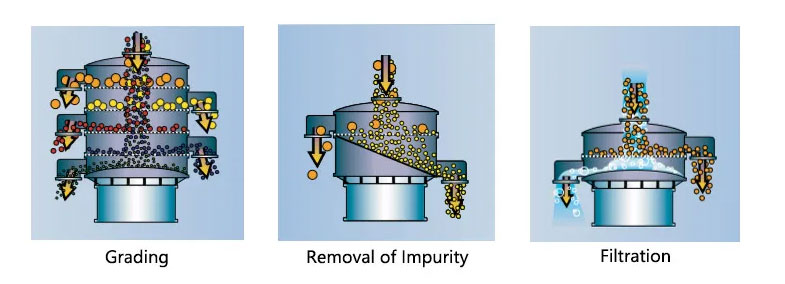

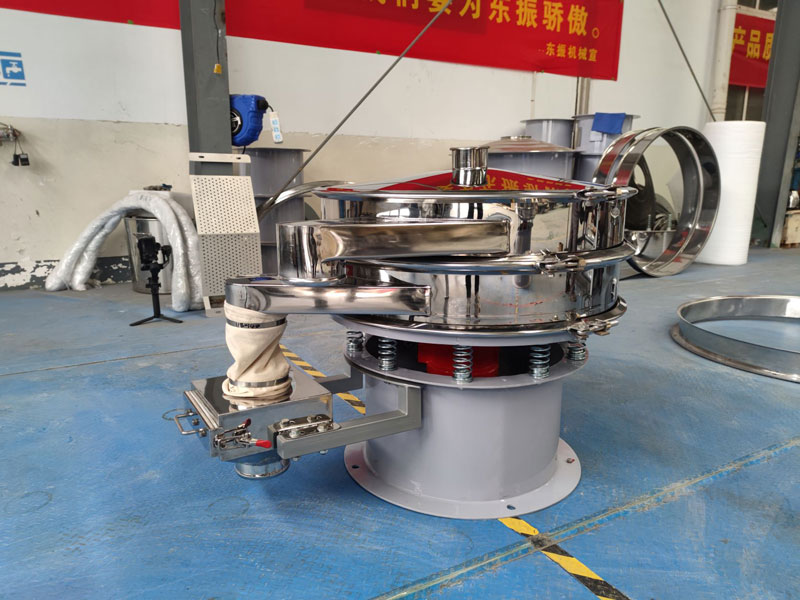

Urea particle vibrating screen, also called vibrating screen machine, is a special screening equipment. It separates granular raw materials into multiple particles of different sizes through vibration. The vibration motor used in the urea granule vibrating screen is a linear vibration motor, and the vibration frequency and amplitude of the motor can be adjusted freely to meet the screening requirements of different materials.

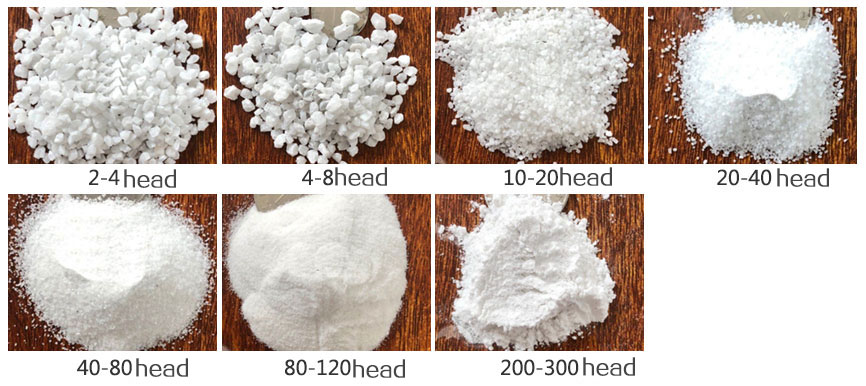

The working principle of the urea granule vibrating screen is very simple. The raw material enters the vibrating screen machine through the feed port, and is subjected to the vibration force, and the granular raw material moves on the screen. Larger particles cannot pass through the pores of the screen and are blocked above the screen to form a layer of particles that cannot pass through the screen holes. Smaller particles are able to pass through the mesh and fall below the mesh, forming a layer of particles that can pass through the mesh. Separation of the particles is thereby achieved.

The urea granule vibrating screen has a wide range of applications. It can be used in the production process of urea to screen out suitable particle size, improve the quality of urea products and optimize the production process. In addition, the urea particle vibrating screen can be used in food processing, cosmetics production and other fields to screen raw materials containing tiny particles to obtain a suitable particle size and improve product quality.

The urea granule vibrating screen has many advantages. First of all, it can efficiently complete the screening work of particles. Secondly, the vibration force can effectively prevent the clogging of the screen hole and prolong the service life of the screen. In addition, the sieve machine has a simple design for easy maintenance and cleaning.

When using the urea particle vibrating screen, pay attention to the following points. First of all, it is necessary to pay attention to the installation and adjustment of the vibration force and amplitude of the vibrating screen machine to meet the required screening requirements. Secondly, the screen should be cleaned in time to avoid its clogging and affect the screening efficiency. Finally, attention should be paid to the maintenance and maintenance of the screening machine to ensure the screening effect and service life.

The urea granule vibrating screen is a very important screening equipment, which can efficiently sieve and finely process urea granules. It has many advantages, such as easy to use and high screening efficiency. However, some details need to be paid attention to in order to achieve the best screening effect.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.