A vertical screw conveyor is a compact design that lifts bulk materials by utilizing a rotating shaft within a fully enclosed housing that consistently moves the product upwards. The following will introduce the advantages of vertical screw conveyors.

It removes product from a hopper or bin into the process stream at a specified rate, ensuring automated, precise product portioning.

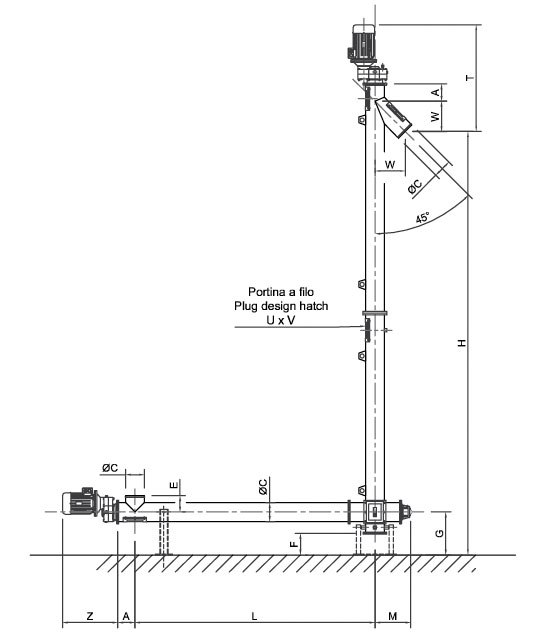

The vertical screw conveyor is composed of a horizontal feeding screw and a vertical screw. The material is fed from the silo or hopper or from the upstream feeding device to ensure that the feeding material has sufficient silo pressure to ensure that the material can be smoothly conveyed upward, and the vertical lifting height can reach 8 meters.

Compact in design so it does not take up a lot of floor space, the conveyor is suitable for most plant layouts.

The screw conveyor is completely enclosed, ensuring no product spillage and waste, reducing dust contamination, which also ensures that no contamination affects your employees, reducing associated costs.

The vertical screw assembly consists of a horizontal screw feeder mounted below the silo or hopper, the vertical machine is fed by a horizontal feed screw synchronized with the feed rate and speed, and the screw conveyor drive drives the feed screw and vertical screw.

You can use it to discharge material in any direction, so material can be discharged through openings in a vertical screw similar to those on a horizontal conveyor, in some cases by connecting a discharge opening to an elbow or through other types of discharge , the material can be transferred to a subsequent conveyor or process.

Above are the 6 major advantages of vertical screw conveyors, for wastewater facilities, wood production, chemical and food, and mining operations, vertical screw conveyors are highly cost-effective, it handles dry and semi-fluid materials, while controlling slow and Free-flowing material, lower costs.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.