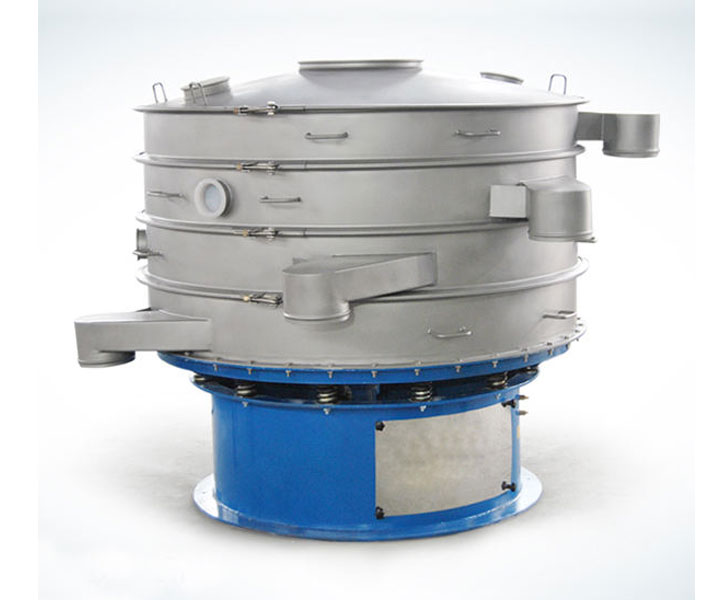

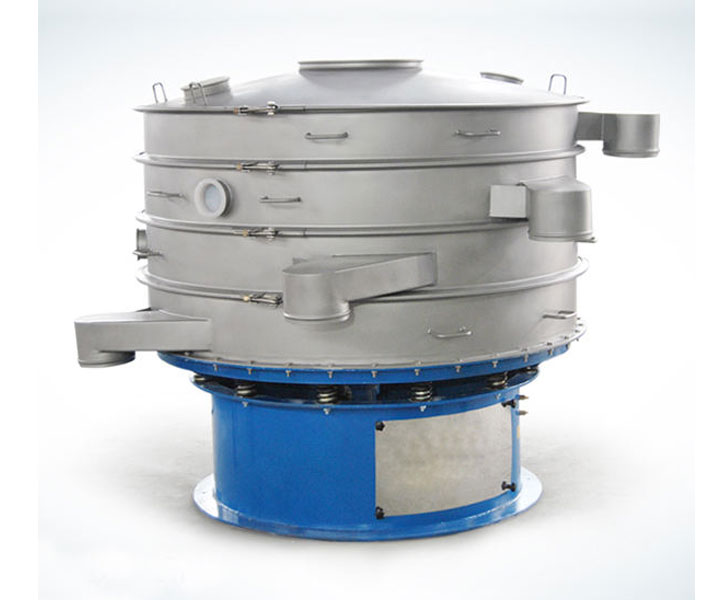

It is used to remove impurities or separate coal particles, and can also realize the screening of coal blocks of different particle sizes.

![]()

![]()

![]()

Price:$800.00-$4,500.00/Set

Consult now and enjoy a 10% discount

Screen Mesh: 10 mm - 400 mesh (38 microns)

Width: 500-1500mm

Length: 2000-4000mm

Capacity: 10Kg-32Tons/Hour

Layer(s): 1-6 Layers

Motor Power: 2*(0.4-3.7)kw(Ordinary type or explosion-proof type optional)

Deck inclination: 0-15°

During the storage process of coal, impurities such as woven bags, metals, and wood chips are easily mixed in. Impurities that are difficult to be ground tend to remain in their original state or become wood chips and threads mixed in the finished coal powder and enter the coal injection system. Blast furnace coal injection The inner diameter of the spray gun is 12mm-18mm, which is easy to be blocked by debris and cause the coal injection system to be paralyzed.

The main purpose of the Pulverized coal vibrating sifter is to remove impurities in the pulverized coal, prevent sawdust, fibers and other sundries from entering the pulverized coal bin, and ensure the normal transportation of pulverized coal in the pipeline.

The selection range of the screen mesh aperture is 2-5mm. If the coal powder is fine, you can choose a 400-mesh screen, or choose an ultrasonic screening system.

Pulverized coal vibrating sifter is mainly composed of screen box, screen frame, screen mesh, vibration motor, motor base, vibration damping spring, bracket and so on.

1. Screen box: It is welded by several steel plates with different thicknesses. It is the main component of the screen machine and also the carrying space for coal powder.

2. Screen frame: There are two materials of wood or metal, the purpose is to keep the screen flat, ensure the accuracy of coal powder screening, and avoid the rapid damage of the screen.

3. Screen: There are several materials such as low carbon steel, brass, bronze, stainless steel wire, etc., and you can choose the form of woven wire or punched plate screen.

4. Vibration motor: The motor of the Pulverized coal vibrating sifter is sealed and explosion-proof, and the speed and power can be adjusted or not.

5. Motor pedestal: It is used to install the load-bearing vibration motor. The connecting screws must be tightened before use, especially three days before the trial of the new screen machine, it must be tightened repeatedly to avoid loosening and causing accidents.

6. Vibration damping spring: prevent vibration from being transmitted to the ground, and at the same time support the full weight of the screen box. When installing, the spring must be perpendicular to the ground.

7. Bracket: It is composed of four pillars and two channel steels, supporting the screen box. When installing, the pillars must be vertical to the ground, and the channel steels under the two pillars should be parallel to each other.

After the pulverized coal is fed into the Pulverized coal vibrating sifter, under the action of the exciting force transmitted by the vibrating motor to the screen surface, the pulverized coal spreads on the screen surface and jumps forward evenly along the screen surface, and the oversized coal powder Or the large particles of impurities are intercepted above the screen, and the pulverized coal that meets the specifications is allowed to enter the lower screen box through the screen. Impurities and qualified pulverized coal can be separated and discharged from the corresponding outlet.

| Model | Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers | Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

Advantages of Pulverized coal vibrating sifter

1. The sieve cover can be added to form a fully sealed coal powder screening space to avoid pollution caused by coal powder diffusion or harm to the health of the staff.

2. The mesh size of the screen can range from 2 mesh to 400 mesh, which can handle coal raw materials such as coal and coal powder.

3. The screen mesh is detachable and replaceable, which can be replaced by itself, and the service life of the machine is longer.

4. The screening output can reach 0.12-32t/h, and the automatic discharge can be connected to the production line for use.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.