If you have such confusion, please take a look at this article. I hope I can help you understand a little.

First of all, before choosing the blades of the screw conveyor, we need to know which kinds of screw blades of the screw conveyor are divided into.

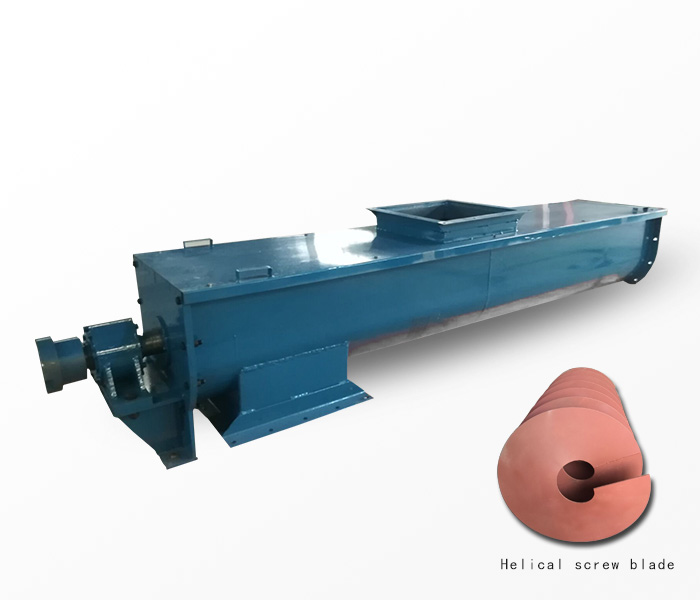

• Solid helicoid

• Belt helicoid

• Blade helical surface

Solid helical blade is suitable for loose materials, which belongs to fixed device and can not be adjusted at will. The helical pitch of belt helical surface is the same as the diameter of helical blade, and it is suitable for conveying powder and small pieces of material.

Blade helical surface is less used, mainly used for conveying viscous and compressible materials. In the process of conveying, mixing and other processes are completed, and the flow of materials can be controlled. Therefore, when choosing the blade of screw conveyor, we should take into account the requirements of application industry, conveying materials, blade technology and so on.

Blade helical surface is less used, mainly used for conveying viscous and compressible materials. In the process of conveying, mixing and other processes are completed, and the flow of materials can be controlled. Therefore, when choosing the blade of screw conveyor, we should take into account the requirements of application industry, conveying materials, blade technology and so on.

Blade is the main part of screw conveyor for conveying material. The selection of blade also determines the conveying power of conveyor. Blade should be selected according to the nature of conveying material. The main reason is that the friction force between the material and the material trough will be formed in the process of transportation. In the process of upward transportation, the material must overcome the friction resistance of the blade to the material and the gravity of the material itself, so as to ensure the material transportation.

In order to reduce the friction force, the manufacturer designs many kinds of blades according to the different characteristics of materials in the design process, so the selection should be based on the material. Select the nature.

The screw conveyor is used to regularly control and continuously transport powder and small pieces of material, such as grain, feed, coal powder, cement, clinker, compound fertilizer, sand, cereals, coal, stones, etc. The structure of screw conveyor is simple and novel, easy to maintain, advanced technical indicators, small cross-section size, good sealing performance, safe and convenient operation, convenient for intermediate loading and unloading; the intermediate suspension bearing adopts rolling or sliding structure, with dust-proof and sealing devices, easy operation and maintenance.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.