The screw conveyor is different in size, shape and material according to different materials. The shape and function of several types of screw conveyor blades are introduced below for your reference.

Standard Pitch Single-Head Conical Spiral - The diameter of the spiral blade is gradually increased from 2/3 to full diameter called a conical spiral. Used for the screw feeder to evenly remove the bulk material from the silo. Compared with variable pitch spirals, they work the same but are more economical.

Standard Pitch Double-Head Conical Spiral - This type of screw is used for feedstocks with easy-flowing materials that are unloaded uniformly from the silo along the entire length of the discharge port.

Standard Pitch Single-Head Ribbon Spiral - This spiral is typically used to transport viscous, viscous or viscous materials. Since these materials are easy to adhere to the solid spiral blades and the shaft, and space is left between the belt blades and the shaft, the strip blades can be used to prevent material from sticking and accumulating.

Single-headed helix with standard pitch and paddle - This spiral is a combination of solid helix and blade. The direction of the blade is opposite to the direction of material flow, and the material can be fully and moderately mixed in the flow of the moving material and the controlled material.

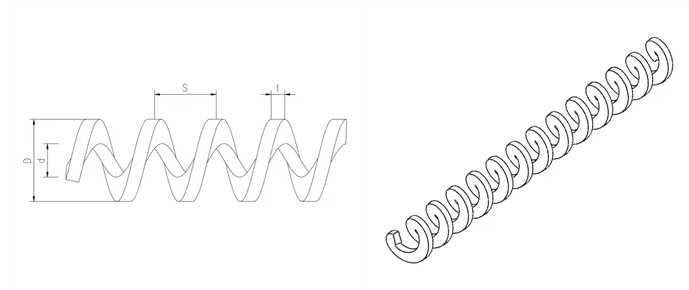

Standard Pitch Sawtooth Single-Head Spiral - Regularly sawtooth is equidistant on the outer edge of the spiral so that the material is moderately agitated during movement. Generally used to transport materials that are prone to agglomeration.

Standard Pitch Single-Head Spiral - The pitch of the conveyor helix is equal to the diameter of the helix and is called the standard pitch. This type of spiral has a wide adaptability to materials and is often used.

Short pitch single - the reduction of the pitch to 2/3 diameter is called the short pitch. Recommended for inclined conveyors with an inclination of more than 20 degrees, even for vertical use. It can also be used in a screw feeder. The shorter pitch prevents the fluidized material from self-flowing.

Standard Pitch Double-Head Spiral - enables smooth material transport and regular flow, ensuring uniform delivery for certain types of materials.

Short-pitch double-headed spiral – This spiral allows materials with fluid properties to flow smoothly and regularly.

Long-pitch single-headed spirals—usually used to agitate fluidized materials or to quickly transport highly fluid materials.

Multi-head ribbon spiral - this type of spiral consists of two or more strip-shaped spiral blades of different diameters. The ribbon-shaped spiral blades are left and right helix, one blade is nested inside the other, through the rigid lug. Connected to the same tube or shaft. One ribbon blade moves the material forward and the other ribbon blade moves the material backwards, which allows the material to be mixed absolutely and fully.

Variable pitch single-headed spiral - This spiral with increasing pitch is used in a screw feeder to evenly discharge powdery, flowable material along the entire length of the inlet.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.