The vibratory screen often has a phenomenon of blocking the net during use. At this time, the cleaning device will come in handy. The vibratory screen cleaning device can quickly and quickly separate the sticky materials deposited on the screen surface, and the mesh has already been separated. The clogged material is cleaned and sieved to make the entire automated screening process smooth and efficient. It’s not enough to know that, you still need to know what are the common cleaning devices?

The ball trays are the most common vibratory screen cleaning device, which is suitable for most granular material screening operations. The appearance is spherical, and the bouncing ball is installed in the middle of the subnet of the vibratory screen and the parent mesh. During the working process, the bouncing ball reciprocates and bounces against the material adhered on the subnet to increase the permeability of the material, thereby effectively Avoid material blockage of the screen and increase the screening output.

Material: It can be divided into rubber material and silicone material. Rubber ball trays are generally suitable for the screening process of general materials. Compared with the rubber ball trays, the silicone ball trays has better elasticity, better wear resistance, and is not suitable for falling off. It is generally suitable for screening of food, medicine and other materials.

The rotary brushes are suitable for spherical, crystalline and brittle materials. It is mainly composed of two sets of cylindrical silica gel (the number is related to the diameter of the screen frame). The rotary brushes are installed at the center of the screen frame, and the coupling is connected. When the sieve machine is started, the rotary brushes are started at the same time, thereby performing the bottom of the sieve frame.

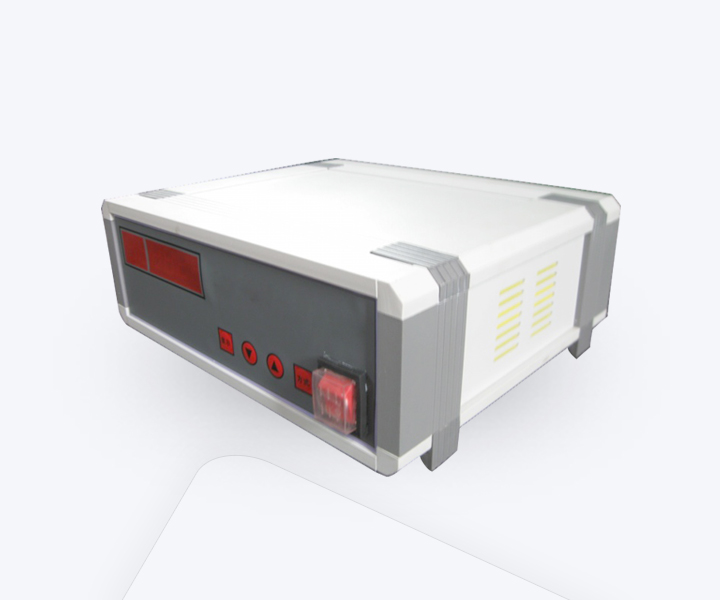

The ultrasonic cleaning device Is the most expensive but most efficient device,it uses the ultrasonic vibration wave to clean the screen, which is suitable for the processing of fine materials. It is mainly composed of ultrasonic power supply, transducer and ultrasonic grid. The ultrasonic cleaning device converts the conventional electricity into 18KHZ high-frequency electric energy through the ultrasonic power supply, and then acts on the grid through the transducer, thereby completing the entire cleaning process. Ultrasonic cleaning equipment is specially designed to solve the fine materials below 500 mesh or some materials with adsorption, static electricity, sticky clumping, light specific gravity, etc. Therefore, it is necessary to consider the screening materials when selecting this kind of cleaning equipment. The characteristics are reasonably selected.

The above is an introduction to the three types of cleaning methods commonly used in vibratory screens, and I hope to help you.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.