Corn starch is an essential food in our life. Its water content is not felt by hand. However, according to reliable data, when the water content of corn starch is between 12% and 13%, it is sieved using a vibrating sieve. The highest efficiency, which equipment can screen cornstarch? Dahan Xiaobian introduces you to three common equipment for sieving corn starch and conducts a brief analysis:

Usually, the mesh size of corn starch is between 80 mesh and 100 mesh. The number of meshes screened by different manufacturers is slightly different. The output required by customers is 4-5 tons, because the water content is 12 %-13% of corn starch has good fluidity, so it is only necessary to use 1800 type vibrating sieve to meet the production, and the screening accuracy is over 95%.

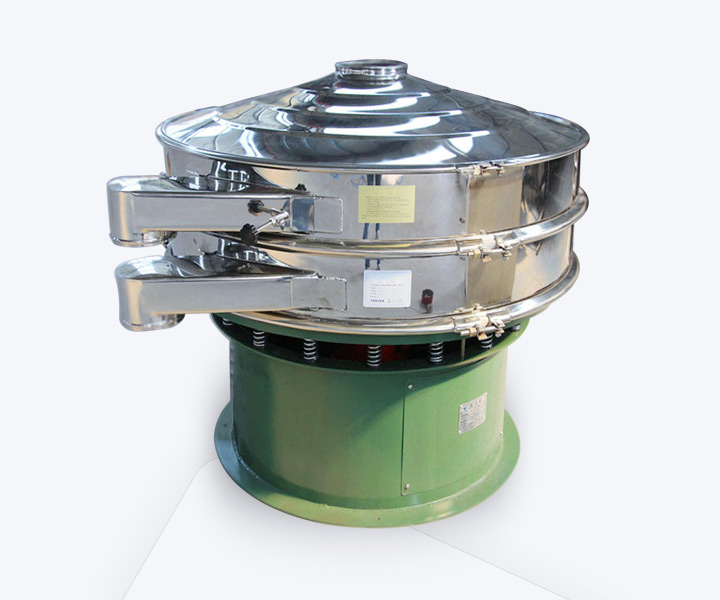

Summary: As a high-precision fine powder screening equipment, the vibro sifter can be sieved up to 500 mesh (28 microns), but the output of the vibro sifter is limited and cannot meet the screening requirements of large output.

Because corn starch is a food in daily life and has strict requirements on hygiene standards, Dahan Company has developed a food grade vibrating screen mainly used in food and pharmaceutical industries. The whole machine is made of 304 stainless steel or 316 stainless steel. The parts in contact with the material are not allowed to be contaminated by any impurities. The vibrating screen seals are equipped with food-grade sanitary standards. The vibrating screen seals are made of silicone material and can be sieved to 500 mesh or 0.028 mm. In addition, Dahan food vibrating screen can have single or multi-layer design, users need to make reasonable choice according to their actual production needs, but too many layers will affect the screening accuracy.

Summary: Although the food grade vibrating screen meets the hygienic standards and screening accuracy in the screening process, it still does not meet the requirements of industries with large screening output.

With the more advanced production equipment and the improvement of production level, the production output of corn starch is no longer limited to 4-5 tons. When the output of screening is as high as 6-8 tons, the same type of rocking screen can be selected for transformation. The imitation artificial design principle of Xinxiang Dahan YBS swing screen is a high-efficiency screening machine specially designed to meet the needs of large-volume, high-precision screening. The screening accuracy can be as high as 90%-95%.

Summary: For the 30-mesh coarse material, the output of the tunmbler sifter and the rocking screen are basically the same. For the fine-to-500-mesh material (such as corn starch), the output of the rocking sieve is much higher than that of the ordinary vibrating screen. The vibrating screen is 5-10 times, but the screening accuracy of the swing screen is slightly inferior to the above two vibrating screens.

From the above information, no matter which screening equipment is selected, different types of vibrating screens have their own unique advantages, and they must have their own shortcomings. Customers also need to order according to actual production requirements.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.