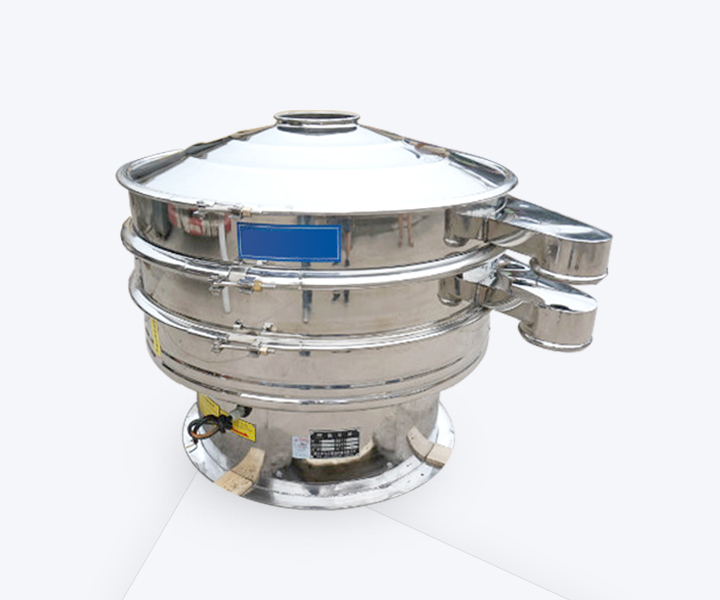

The vibrating screen is a fine screening equipment. Users often encounter mixing and other phenomena during the screening process, which seriously affects the screening accuracy of the vibrating screen. For such phenomena, the vibrating screen appears mixed during the screening process. How to do? The following are the following solutions for the Dahan professional and technical personnel to summarize.

In addition to the fully enclosed structure to ensure the sealing performance, the vibrating screen generally uses a sealing strip between the screen frame and the screen body to seal and protect the vibrating screen. The vibrating screen sealing strip is mainly made of rubber material and Silica gel material, but the vibrating screen will generate heat and friction during the screening process. In the long run, it will affect the vibrating screen sealing strip. Some bad sealing strips will be deformed, which will affect the sealing performance of the vibrating screen equipment. Once the sealing is not good, mixing will occur during the screening process. Therefore, Dahan Machinery recommends that users should regularly check whether the seal ring is deformed when using the vibrating screen. If the deformation is found, it should be replaced in time.

As a part directly contacting the material, the screen is mainly for classifying and removing impurities. However, due to the different materials of the sieve, the specifications and materials of the screen are different, so if the screen is not suitable. When the sieve machine is operated for a long time, it is easy to cause damage to the sieve of the vibrating screen, so that the material is mixed during the screening process. Therefore, the user should replace the damaged screen in time. The rotary vibrating screen produced by Xinxiang Dahan can be changed in 3-5 minutes, and 1~2 people can complete the operation.

Small particle materials and large particle materials cannot be completely classified. This situation is mostly caused by the motor being used for too long. It can be adjusted by adjusting the motor excitation force or replacing a new motor. If the excitation force is too small, the screening may be incomplete. .

In the actual screening process, when some materials have problems such as viscosity, strong adsorption, static electricity, etc., the use of the vibrating screen will cause problems such as agglomeration and agglomeration, and the phenomenon of mixing will occur when sieving, so For materials with characteristics such as viscosity, adsorption, static electricity, light specific gravity, Dahan Xiaobian recommends that users use ultrasonic vibrating screens.

The above is the solution for the mixture in the production process of the vibrating screen. If you can't solve your current problem, please consult the regular manufacturer in time. The Xinxiang Dahan manufacturer can provide you with professional free consultation.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.