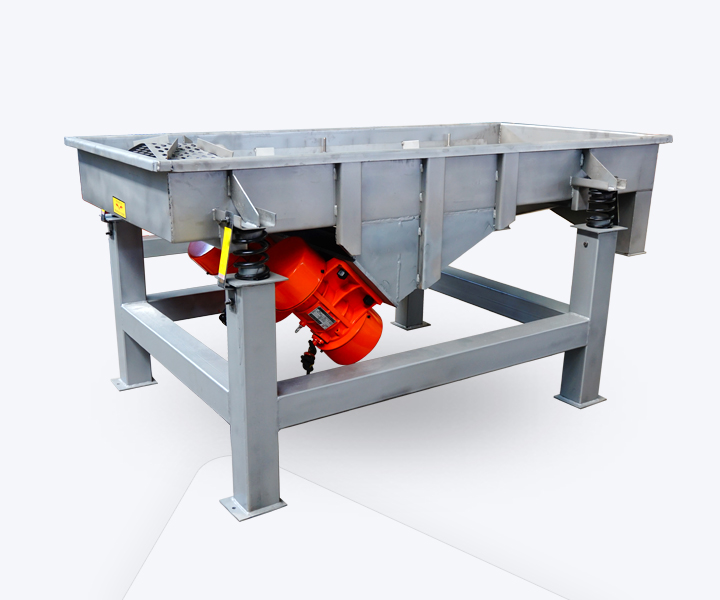

Linear vibrating screen is a type of screening machine designed to meet the needs of large-volume production and high screening efficiency. The efficiency of linear vibrating screen depends on its unique rectangular wide-screen screen. The large-area effective screening area and the high-efficiency discharge speed of the composition, the effective screening area of the linear vibrating screen under the corresponding specifications is fixed, then the factors affecting the efficiency of the linear vibrating screen are mainly focused on the discharging speed. This variable. So what are the reasons that affect the speed of the linear vibrating screen? The following is the relevant introduction:

In simple terms, the linear vibrating screen mainly uses the vibration motor vibration source to make the material jump on the screen, and pushes the material with a certain amount of exciting force in a fixed direction. Therefore, the inclination angle of the vibration motor determines the speed at which the material is sieved and discharged. The tilt angle of the motor of the linear vibrating screen is generally fixed. The direction of the exciting force can be adjusted by adjusting the angle of the eccentric block at both ends of the vibrating motor. The angle of the adjusting angle should be as needed according to the material condition and the processing amount. Adjust, you can ask the linear vibration screen after the sale to let it know the adjustment method.

Although the damping spring of the linear vibrating screen is only a small accessory on the equipment, it usually plays the role of noise reduction and buffering, but the damping spring is no less important than the vibration motor mentioned above. Because of its shock absorption and noise reduction effect, it can not only maintain the balance of the overall force of the vibration screening machine and the stability of the work, but also effectively avoid the damage of the screen frame caused by the aftershock, the damage of the screen, and the like. If it is not working properly, it plays an important role in maintaining the stability of the vibrating screen and prolonging the life.

The damping spring is divided into rubber, spiral steel spring and composite spring. For spiral steel springs, the strength of the shock absorber springs with different thicknesses is also different. If the size of the vibrating screen is large or the exciting force of the vibrating motor is too strong, the use of a thinner damping spring may cause the spring to break, thereby affecting the normal operation of the vibrating screen, causing the material to run off and affect the discharge speed.

The linear vibrating screen box has restricted the range of movement of the material during the process of removing the impurities, that is, following the sieve area of the rectangular screen, so that the material can complete the screening process efficiently and quickly according to the established motion track inside the vibrating screen. Preventing the overflow of materials and causing waste. When working in a linear vibrating screen, the screen box including the screen frame needs to simultaneously withstand the gravity of the screening material and the strong exciting force of the vibration motor. If the strength is insufficient, the screen frame is easily deformed and damaged. Therefore, the phenomenon that the screen is not flat or even damaged, directly affects the accuracy of the material classification and the discharge speed.

Therefore, if there is no special requirement in the industry, the linear vibrating screen box generally chooses carbon steel as the main material, and in order to ensure the shock resistance and service life of the screen box, the thickness of the screen box is generally required to be composed of 6~16mm steel plate or angle steel. . In the case of linear screens in the food industry or the pharmaceutical industry, the screen box material is replaced by a stainless steel plate of a certain thickness.

In addition, in addition to material requirements, the strength of the linear vibrating screen box requires a unique welding process and a robust design. The connection method of the screen box is usually welded, and the welding structure is simple to construct, but the internal stress is large due to the complicated weld seam. Under strong vibration load, weld cracking or even component fracture may occur. In order to remove the internal stress of the welded structure, tempering treatment is adopted. It should be noted that angle steel can be added to supplement the rigidity when necessary, so that the whole screen box can be more shock-resistant, enhance the overall service life of the linear vibrating screen, and prevent the screening area from being damaged due to the deformation of the screen box. Subject to restrictions.

It can be seen that the discharge speed of the linear vibrating screen is not determined by a certain factor, but the result of multiple details working together. Therefore, in the daily use of the linear vibrating screen, it is necessary to select a normal high-quality linear vibration. Under the premise of screening, do regular maintenance and maintenance of the equipment, and regularly check and maintain the equipment. If a part is aging loose, it is likely that the entire screen of the linear vibrating screen will be uneven and the screen body will be unstable, causing the material to run off. In severe cases, even abnormal noise and serious wear will occur. Serious problems with vibrating screen efficiency and accuracy.

The above information hopes to help you.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.