Wheat bran is the product of wheat peeling. Raw unprocessed mash contains crushed wheat, husks and other impurities. It needs to be sieved with a vibrating sieve. Which kind of vibrating sieve is selected by wheat sifting? Dahan recommends centrifugal sifter for you. The main reasons are as follows:

The centrifugal sifter can use air as a carrier.

Screening of light-weight materials has always been a screening problem for many customers. It is precisely because of the light weight of wheat bran, it is difficult to screen using ordinary vibrating screen.

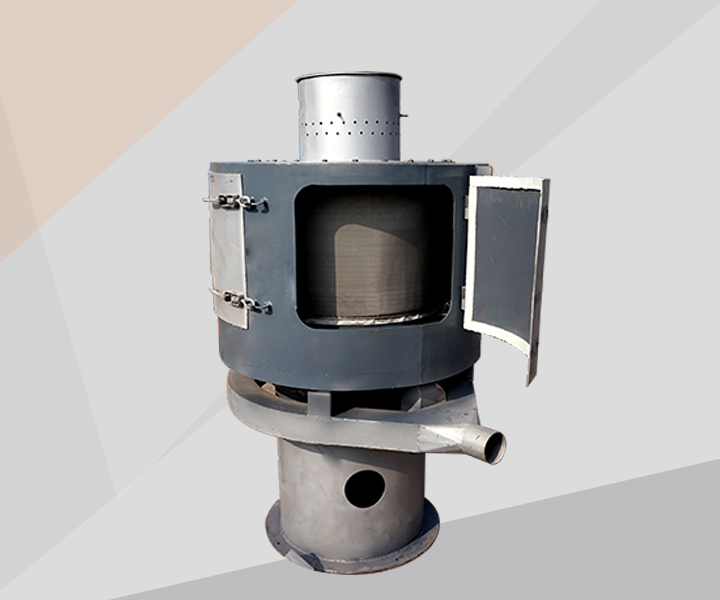

The centrifugal sifter utilizes the characteristics of small mass, light weight, good fluidity and easy floating. The wheat bran is fully diffused into the airflow, so that the wheat mash passes through the screen with a single particle in sequence, and passes through the negative pressure airflow. After mixing the material with the air, it enters the middle of the screen wind wheel, and applies sufficient centrifugal force through the wind wheel blade to spray the net through the barrel type sieve, and collects through the volute to realize the screening purpose of the wheat stubble.

The output of centrifugal sifter is 5-10 times or higher than that of ordinary vibrating screen.

Users who screened wheat bran generally require a large yield of screening, and some vibrating screen equipment cannot be satisfied.

The air flow screen can be used in conjunction with the wind turbine. It can be operated with a pulse dust collector for a long time. The processing capacity is large, the screening efficiency can reach more than 95%, and the output can reach 10 tons per hour. It is 5-10 for ordinary vibrating screen. Multiple or higher.

The centrifugal sifter has no dust pollution

Wheat bran is a kind of crop, which contains a lot of dust, so dust will appear in the screening process, which will affect the screening environment.

The screening process of the centrifugal sifter is carried out under the condition of negative pressure and half cycle, and the operation can be continuously performed without dust pollution, the energy consumption of the sieve machine is low, and the energy saving and environmental protection are more.

Interested friends can click on the online consultation or visit the factory. Dahan provides free guidance and consultation.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.