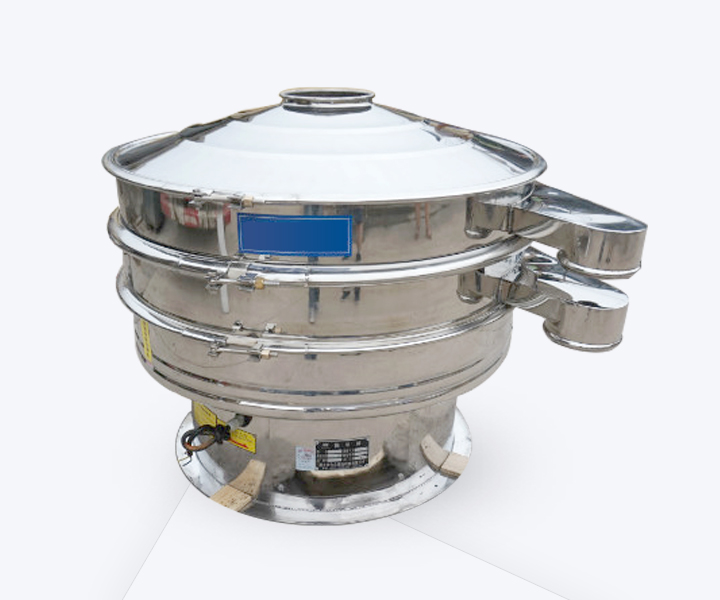

The best choice for graphite powder screening -Powder sifter machine

The graphite powder has a light specific gravity and a fine particle size of 90 to 20 microns, which is easy to hold and has good fluidity. Ordinary vibrating screen will cause material agglomeration and leakage during the screening process, which will cause serious blockage. powder sifter machine is equipped with an ultrasonic device,which converts 220V, 50Hz or 110V, 60Hz electric energy into 18KHz high frequency electric energy, and then,the transducer is turned into 18KHz mechanical vibration, so that the graphite powder on the sieve surface is always kept in suspension, which effectively solves the problem of blocking the mesh.

The material has a wide application range and is suitable for separating the powder from 50~625 mesh screen, decomposing the adhering substance and reducing the sieve material, and the screening precision can be improved by 1-70%.

Due to the addition of the ultrasonic screening system, the powder sifter machine produces 2-10 times of the ordinary vibrating screen when sieving powder, granules and slurry materials, which is 5-20 times higher than that of the vibrating screen without ultrasonic.

Therefore, in combination with the above analysis, the user can select powder sifter machine when sieving the graphite powder.

If you need help, feel free to ask us or leave a message and we will get back to you as soon as possible.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.