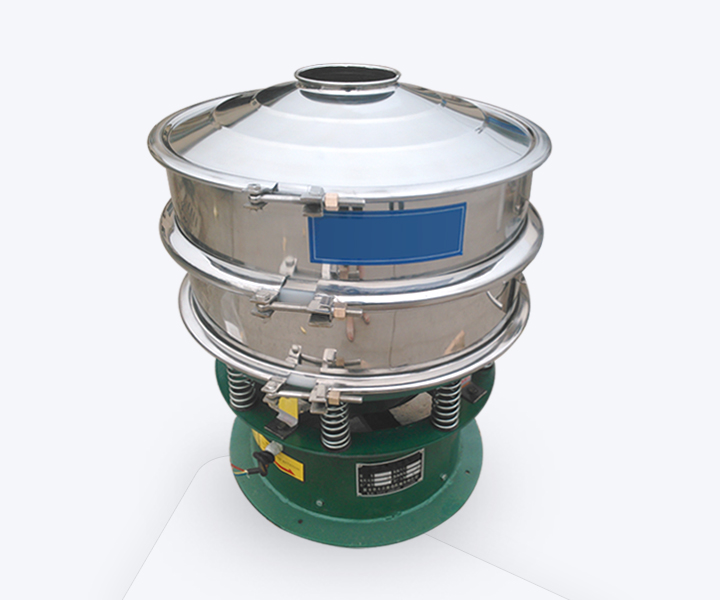

Vibrating screens are produced in the production market for the inefficiency of traditional screening and impurity removal methods, which are increasingly difficult to meet the production speed requirements of enterprises. Therefore, the working efficiency of vibrating screens is the basis of vibrating screens in the market, and the efficiency is not up to standard. The vibrating screen is no different from a pile of scrap iron. However, in the actual production process, there will always be a situation in which the customer feedback screening machine will have slow efficiency such as slow material feeding and slow discharge, etc. How should this be solved?

Therefore, many users use the first feeling that this is a problem with the machine. It is definitely not designed when the manufacturer designs it. In fact, there are many reasons for the slow discharge of the vibrating screen. The use time of the equipment and the vibration screening type are correct. Whether it is or not, some can be corrected only by a very simple operation, and there is no need to replace the device at all. The details are as follows:

First of all, if the equipment you just bought is used for the first time, first check if the screen of the discharge port and the equipment are at the same level. If it is not at the same level, then this is completely a design. Vibrating screens with serious defects should be contacted immediately by the manufacturer for return or replacement. Regular manufacturers generally do not make such mistakes, even if they are found, they should be found and corrected in the test machine before leaving the factory.

If there is no situation that the screen of the discharge port and the sieve machine are not at the same level, the next step should be to check whether the whole machine is working in a horizontal state, if it is because the whole device is not at the level The phenomenon of difficulty in exhausting can be solved by increasing or decreasing the damping feet of the vibrating screen. If you do not operate, you can contact the manufacturer for consultation or assistance.

The angle of the weight change, the movement track and residence time of the material on the screen will change, the larger the angle, the smaller the eccentric force generated, and the longer the material stays on the screen. The finer the division, the slower the discharge rate will be. On the contrary, the smaller the angle, the larger the eccentric force will be, and the residence time of the material will become shorter. Correspondingly, the discharge speed will be shorter. accelerate. This type of adjustment is more suitable for coarse drying and screening of larger particles. Therefore, the user should adjust the angle between the two weights according to the nature of the material to be sieved, so that the distribution, processing volume and over-network rate of the materials can reach the optimal screening state.

Note: The angle of the eccentric block of the vibration motor should be kept ≥5° each time. In addition, the angle of the eccentric block of the vibration motor is too small, which will affect the accuracy of material screening. Therefore, the user should adjust it as appropriate.

Increasing the weight of the eccentric mass can increase the exciting force of the whole machine. The user can increase the weight of the weight according to the number of layers of the vibrating screen and the specific gravity of the material, so that the vibrating screen and the material can reach the expected best. effect.

The solution to the problem of poor discharge and discharge of the vibrating screen is introduced. In short, if you want to buy a professional vibrating screen, you must have a certain understanding of the strength of the manufacturer. Dahan vibrating screen manufacturer has nearly 30 years of experience in R&D and production of screening equipment. All equipments have a professional technical team from the smallest screw fittings to the design and assembly of the whole machine. All equipment will be tested several times before shipment. Please ensure that the equipment is running well before it is shipped.

Please feel free to contact us.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.