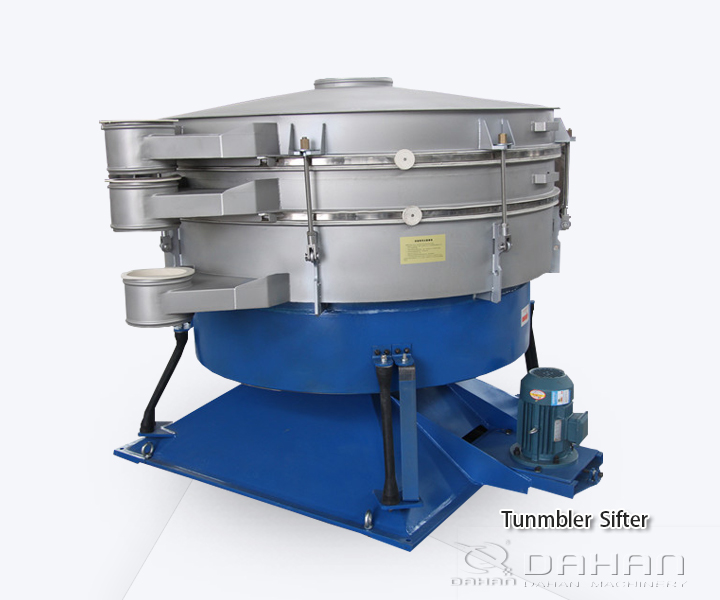

Both the vibro sifter and the tunmbler sifter are very common types of vibro sifters. What is the difference between a tunmbler sifter and a vibro sifter? Next, I will discuss the difference between the vibro sifter and the tunmbler sifter.

The main materials for the vibro sifter are particles, powders and slurry materials.

The tunmbler sifter can effectively screen all fine and ultra-fine powder and particulate materials, especially for the screening of irregular materials such as round shape, cylindrical shape and sheet shape.

The vibro sifter can screen particles as fine as 500 mesh or 0.028 mm, filter 500 mesh slurry, and is equipped with a bouncing ball cleaning device, which can reduce the phenomenon of blockage of materials during the screening process, greatly improving Screening yield and screening efficiency of the screen.

The tunmbler sifter is up to 5 times the output per unit area, and the separation to the 6th level, the screening accuracy is as high as 90~95%, the screening efficiency is as high as 90%-99%, and the screening device is used, such as bouncing ball, ultrasonic wave, etc. Blocked.

The vibro sifter adopts a vertical motor as the excitation source. When the screen machine is started, the eccentric weights installed on the upper and lower ends of the motor convert the rotary motion of the motor into a horizontal, vertical and inclined three-dimensional motion, and then this The movement is transmitted to the screen surface. In this process, the material smaller than the pore size of the sieve surface falls through the sieve hole to the lower layer to become the undersize material, and the material larger than the pore diameter of the sieve surface is discharged from the discharge opening after continuous jumping movement, thereby completing the entire screening process.

The basic rotary motion of the tunmbler sifter is similar to that of the artificial screen. After the rocking screen is connected to the power supply, the screen body is started, and the screen box is driven by the vibration device to make a circular motion. At this time, the screen box drives the entire screen surface for periodic motion. The material on the sieve surface is oriented and jumped along the screen box. In this process, the material smaller than the sieve aperture falls to the lower layer of the screen, and is discharged from the lower discharge port, and the material larger than the sieve aperture is The upper discharge port is discharged, and the intermediate layer is discharged from the middle discharge port, thereby achieving the purpose of screening the material.

Compared with the vibro sifter, the tunmbler sifter is more expensive, because of its characteristics, the vibro sifter is a more cost-effective vibro sifter.

The above is the difference between the vibro sifter and the tunmbler sifter. When purchasing the vibro sifter, the user needs to refer to the materials, screening requirements, purchasing funds, etc., which is suitable for your own material, if you have any questions. You can always consult Xinxiang Dahan online customer service, they will provide you with one-on-one free online guide to help you find a vibro sifter device that is more suitable for you.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.