Ultrasonic sifter is the most ideal equipment for solving screen plugging. It is the best choice when users choose to screen materials with strong adsorption, high static and easy agglomeration. However, in the actual use of Ultrasonic sifter, it will inevitably fail. Today, Xiaobian will introduce the common faults of Ultrasonic sifters and give practical solutions.

As the leader of fine screening, ultrasonic screening has the best screening effect in the field of fine powder screening, which can effectively solve the problem of material blocking, but in the actual operation, it is mainly caused by the following two reasons:

1)Due to improper use, etc., the quality of the Ultrasonic sifter may be poor.

2)If the moisture content in the material is too large in the screening material, the mesh may be clogged, and most of the screening materials are accumulated in the screen, causing the upper layer to be too thick.

3)In the process of feeding, if the feeding is not uniform, the quality of the material screening will not meet the requirements.

Solution:

1) If the quality of the Ultrasonic sifter is poor due to improper operation, it is necessary to train the relevant personnel to master the correct operation method.

2) Before sieving the material, the sieved material needs to be analyzed. If the water content of the sieved material is too large, a suitable treatment method can be selected to remove excess water.

3)To ensure uniform feeding

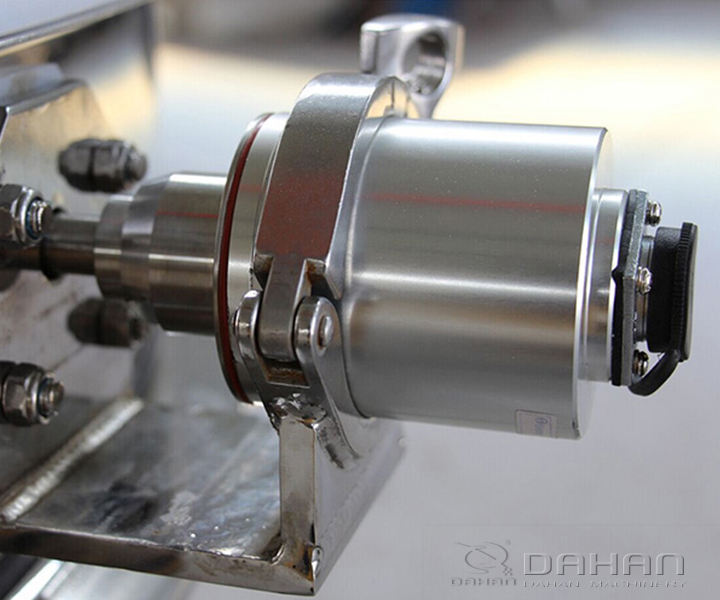

The ultrasonic transducer is the core component of the Ultrasonic sifter. When the Ultrasonic sifter is used for a long time, the ultrasonic transducer will have a high temperature. The user needs special attention at this time. If it is in a high temperature for a long time, it is very easy to Cause damage.

Solution: Stop immediately and check if the ultrasonic transducer and the basic part of the screen are loose, and if there is material residue in the temperature probe part of the transducer.

Ultrasonic sifters exhibit excessive noise during screening. The cause may be caused by bearing damage, loose bolts, broken beams or spring damage.

Solution: Loose bolts can be tightened directly. In all three cases, new parts need to be replaced.

If the Ultrasonic sifter is down, the operator needs to check if the connecting cable is connected and whether the ultrasonic power is turned on.

The above are four common faults and causes analysis of Ultrasonic sifters. If you have other questions, you can always consult Xinxiang Dahan manufacturers, we will provide you with professional technical guidance.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.