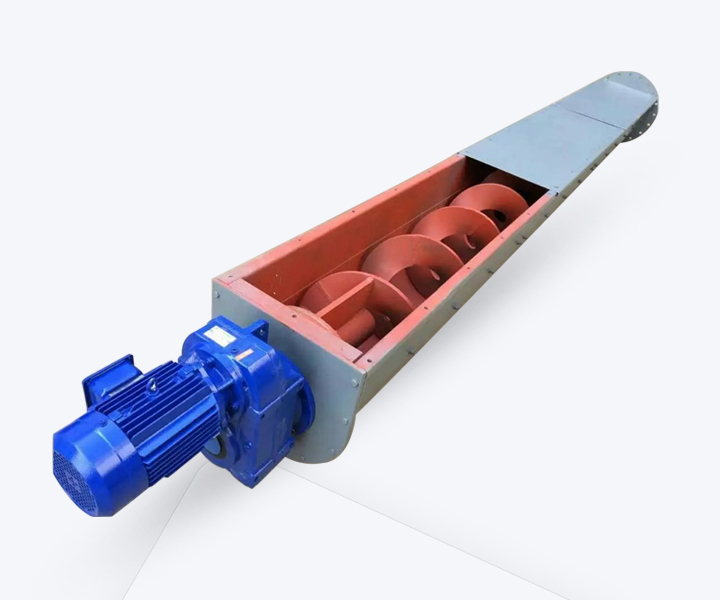

The screw conveyor uses a rotating spiral to transport the conveyed material along a fixed casing for conveying. The direction of rotation of the rotating shaft of the screw conveyor determines the direction of material transport. So what are the factors affecting the conveying efficiency of cement screw conveyors?

The conveying efficiency of the cement screw conveyor is transmitted by the screw conveyor and the motor power. If the power of the cement screw conveyor is too small, it will not be able to achieve friction between the material and the casing, so the power is very different from the conveying efficiency of the cement screw conveyor.

The size of the blade pitch, the conveying capacity of the cement screw conveyor is driven by the blades of the screw conveyor. If the blade pitch is too small, the speed of the blanking will be smaller, and the blade pitch will be higher. The larger it will be, so the size of its blade pitch has a great relationship with the conveying efficiency of the cement screw conveyor.

The size of the elevation angle is the inclination of the cement screw conveyor. If the elevation angle is between 90° and 45°, the conveying energy of the cement screw conveyor will be significantly different. At the same speed, the lower flow rate of 90° is greater than the lower flow rate of 45°, so the 90° cement screw conveyor will have lower conveying efficiency than the 45° cement screw conveyor, while the cement screw conveyor will tilt. The angle is generally not more than 30 °.

In the long-term use of cement screw conveyor, it is inevitable that the following residual materials will accumulate in the spiral casing. If the residual materials in the casing are not cleaned in time, it will accumulate more and more, which will cause a certain degree. The material of the cement screw conveyor is clogged.

If you have other questions, you can consult the customer service staff of Xinxiang Dahan Machinery.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.